servicesPRECISION MACHINE EQUIPMENT

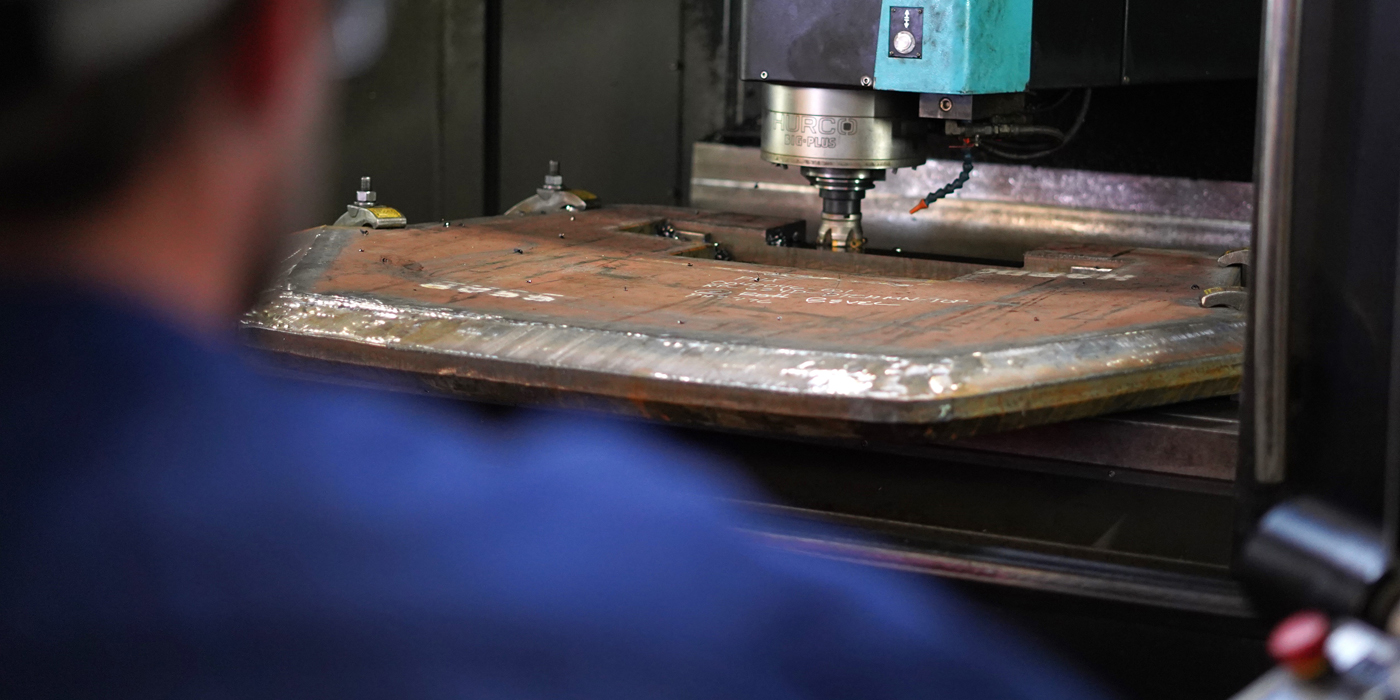

Cutting Edge PRECISION MACHINING

Cutting Edge Supply is equipped on-site with heavy duty General & CNC Machining, allowing us to expedite your custom fabrication, remanufacture or repair job.

Our state-of-the-art machines superiorly handle CNC milling, face-milling, beveling, drilling, boring and tapping of the toughest and strongest steels on the planet, while delivering the tightest tolerances.

Through Chrome Craft, we also have machines for precision grinding, including centerless grinding and I.D. grinding.

Service Locations & MACHINE LISTINGS

Colton, California

-

Hurco VMX84i Vertical CNC Machining Center 3-AXIS CNC Mill (84” X‐axis, 34” Y‐axis, 30” Z‐axis)

-

Hurco VMX50ti Vertical CNC Machining Center 3-AXIS CNC Mill (50” X‐axis, 26” Y‐axis, 24” Z‐axis)

-

Hurco VMX50ti Vertical CNC Machining Center 3-AXIS CNC Mill (50” X‐axis, 26” Y‐axis, 24” Z‐axis)

Sacramento, California

-

Haas 1140948VF-9/50 Vertical CNC Machining Center 3-AXIS CNC Mill (84” X‐axis, 40” Y‐axis, 30” Z‐axis)

-

Precision O.D. Grinder = Up to 156” long center to center

-

Precision I.D. Grinder = 2" I.D. up to 12" I.D.

-

Centerless Grinder = 3" O.D. x 18" length