toolsTooth Identifier

HOW TO IDENTIFY YOUR DIGGING TEETH

Replacing your worn-out digging teeth can sometimes feel challenging, especially with so many options on the market. It’s also sometimes difficult to determine which tooth system you are currently using, as well as the profile and correct sizing of the tooth.

Cutting Edge Supply is here to help you determine the correct replacement part with this handy Tooth Identifier guide.

Steps To Identify and Unknown Tooth

Step 1

Look for a part number on the tooth or shank. Part numbers are often stamped or cast into the tooth. Many brands position the number in a location that does not wear, like near the base or inside of the pocket.

Step 2

How does the tooth lock onto the shank or adapter? What hardware or retainer type is used to secure the tooth?

The most common is either a side pin, diagonal pin or top pin. Alternatively, there can be proprietary hardware, such as newer CAT and ESCO systems that have unique locking mechanisms like a wedge or oblong insert.

You can use our Tooth Identifier chart below to see more examples of the most common tooth systems in the industry, and view Teeth Identifying Photos here.

| RETAINER LOCATION | HOLE SHAPE ON SHANK | RETAINER TYPE | IDENTIFYING NOTE | TOOTH SERIES | AVAILABILITY |

|---|---|---|---|---|---|

| SIDE | ROUND | ROUND PIN & RING | RECTANGULAR POCKET | CAT J SERIES / CAT R SERIES | WE OFFER |

| TOP | NOTCH IN TOP SIDE | WEDGE PIN & LOCK SPRING | HAS TABS/ FLANGES | CAT K SERIES | WE OFFER |

| DIAG | OBLONG OR ROUND | ROUND PIN & RING | PIN INSTALLS RIGHT SIDE FACING BUCKET | CAT DRS | WE OFFER |

| SIDE | NUBS ON SIDE NO HOLES | INCLUDED IN TOOTH | LOCK TURNS TO CLICK | CAT ADVANSYS | OEM ONLY |

| DIAG | OBLONG OR ROUND | ROUND PIN & RING | PIN INSTALLS LEFT/TOP SIDE FACING BUCKET | H&L RHOMBIC | WE OFFER |

| TOP | RECTANGLE | STEEL PIN W/ RUBBER SPRING | ARCH ON TOP OF TOOTH OR FLANGE ON LARGER SIZES | ESCO CONICAL / SUPER CONICAL | WE OFFER |

| BASE OF TOOTH | NO HOLES | HORSESHOE RETAINER & CURVED PIN | HAS TABS/ FLANGES | ESCO HELILOK / VERTALOK | WE OFFER |

| BASE OF TOOTH | NO HOLES | STEEL PIN W/ RUBBER SPRING | HAS TABS/ FLANGES | ESCO SUPER V / SV2 | WE OFFER |

| BASE OF TOOTH | SQUARE ON SIDE | INCLUDED IN TOOTH | RETAINER PRIES UP TO CLICK IN PLACE | ESCO ULTRALOK | WE OFFER |

| TOP | ROUND | STEEL ROLL PIN | ROUND HOLE | HENSLEY PARABOLIC 156 | 160 | 220 | WE OFFER |

| TOP | RECTANGLE | STEEL W/ RUBBER CENTER FLEXPIN | RECTANGULAR HOLE FOR PIN AT TOP | HENSLEY PARABOLIC 290 | 330 | 370 | 400 | 410 | 450 | WE OFFER |

| SIDE | OBLONG | ANVIL SHAPED WITH HEX HEAD | PIN CLICKS IN WITH RATCHET WRENCH | HENSLEY XS | WE OFFER |

| SIDE | TOMBSTONE / BULLET | OBLONG SHAPE WITH HEX HEAD | PIN CLICKS IN WITH RATCHET WRENCH | HENSLEY GETPRO | WE OFFER |

| TOP | ROUND | ROUND PIN & RING | SIMILAR TO J-SERIES PIN BUT VERTICAL | "5" SERIES HENSLEY 295 | 335 | 385 | 435 | 485 | WE OFFER |

| SIDE | OBLONG | RECTANGULAR WITH HEX HEAD | KOMATSU PROPRIETARY NOT SAME AS XS | KOMATSU KMAX | WE OFFER |

| SIDE | OBLONG | RECTANGULAR WITH HEX HEAD | BACKHOE SIZES ONLY NOT SAME AS XS | CASE SMART FIT | OEM ONLY |

| TOP (IN ADAPTER) | RECTANGLE | STEEL PIN W/ RUBBER SPRING | HAS EAR FLANGES | MTG KINGMET | WE OFFER |

| SIDE | ROUND WITH NOTCH | ROUND PIN W/ SOCKET HEAD | LARGE SIZE ONLY 5" POCKET AND UP | MTG STARMET | OEM ONLY |

| TOP (IN ADAPTER) | RECTANGLE | STEEL PIN W/ RUBBER SPRING | HAS EAR FLANGES, VOLVO OEM | VOLVO MET | OEM ONLY |

| SIDE | ROUND | ROUND PIN & RING | LOOKS LIKE J SERIES BUT LARGER HOLES | KOMATSU SIDE PIN | WE OFFER |

| SIDE | ROUND | ROUND PIN & RING | NOTCH ON TOP OF TOOTH POCKET | DAEWOO DOOSAN | OEM ONLY |

| SIDE | ROUND | ROUND PIN & RING | CUT BACK ANGLE ON REAR OF TEETH | HYUNDAI KOBELCO | OEM ONLY |

| SIDE | OBLONG | STEEL W/ RUBBER CENTER FLEXPIN | PIN HOLE IS SO IT'S HIGHER ON TOOTH | COMBI / BOFORS C-LOCK | OEM ONLY |

| TOP | RECTANGLE | STEEL PIN W/ RUBBER SPRING | NOTCHES ON REAR SIDES OF TOOTH | COMBI PROCLAW | OEM ONLY |

| SIDE | OBLONG | STEEL W/ RUBBER CENTER FLEXPIN | FLEX PIN, SMALLER SIZES | H & L ORIGINAL | WE OFFER |

| TOP | OBLONG | STEEL W/ RUBBER CENTER | FLEX PIN TOP LOAD SMALL TO LARGE SIZE | H & L VP SERIES | WE OFFER |

| SIDE | ROUND | ROUND PIN W/ SOCKET HEAD | FITS ON J SERIES (*LOOKS SIMILAR BUT WILL NOT FIT KMAX/XS STYLE) | JOHN DEERE TK / RVJ | OEM ONLY |

| REAR | ROUND | BOLTS ON AT BASE | TOOTH & SHANK ARE ONE PIECE | UNI-TOOTH | WE OFFER |

| NONE | NO HOLES | NONE | CRIMPS ON BY PINCHING SIDEWALL | H&L STYLE CRIMP-ON RIPPER 2A | 3C | 1L | HENSLEY CRIMP-ON | WE OFFER |

| NONE | SLOT OR GROOVE IN TOOTH | NONE | SLIDES ON, HELD ON BY ITS WEDGE SHAPE | SCARIFIER | WE OFFER |

Step 3

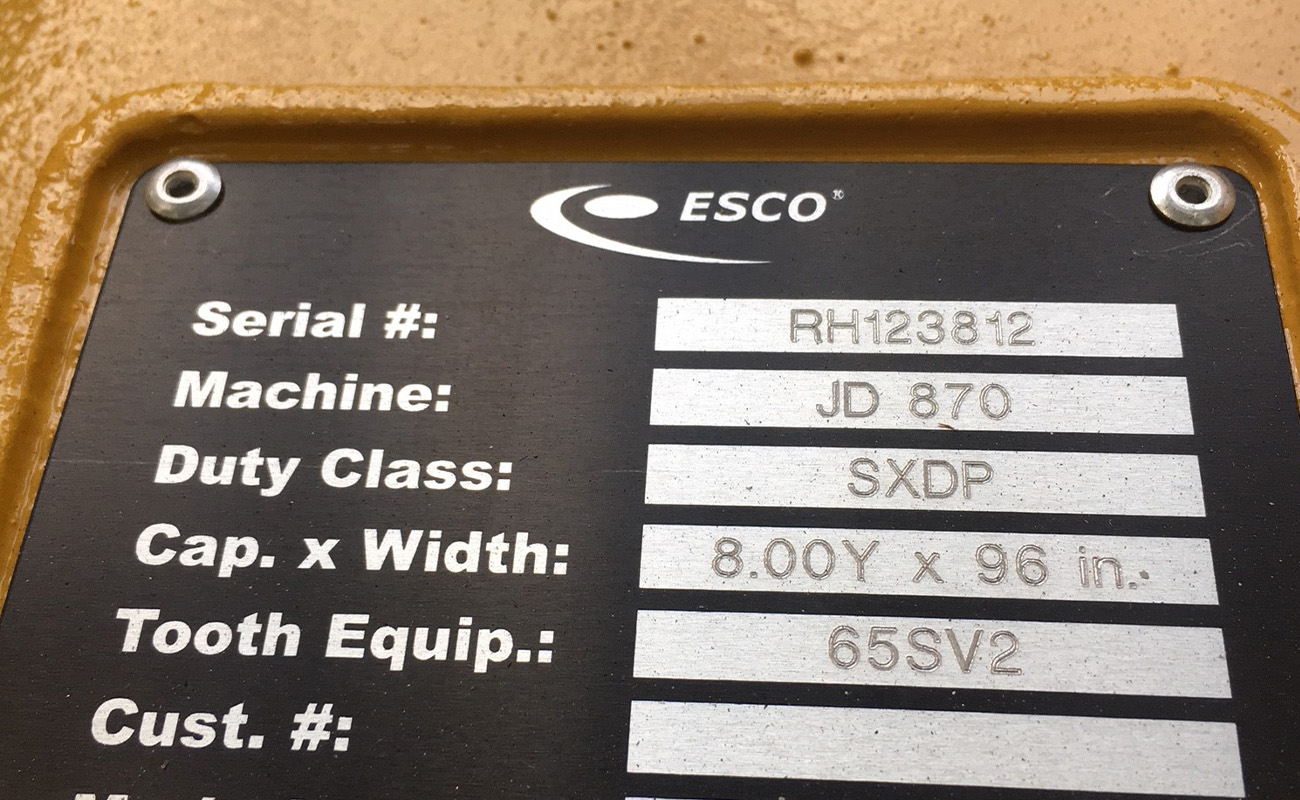

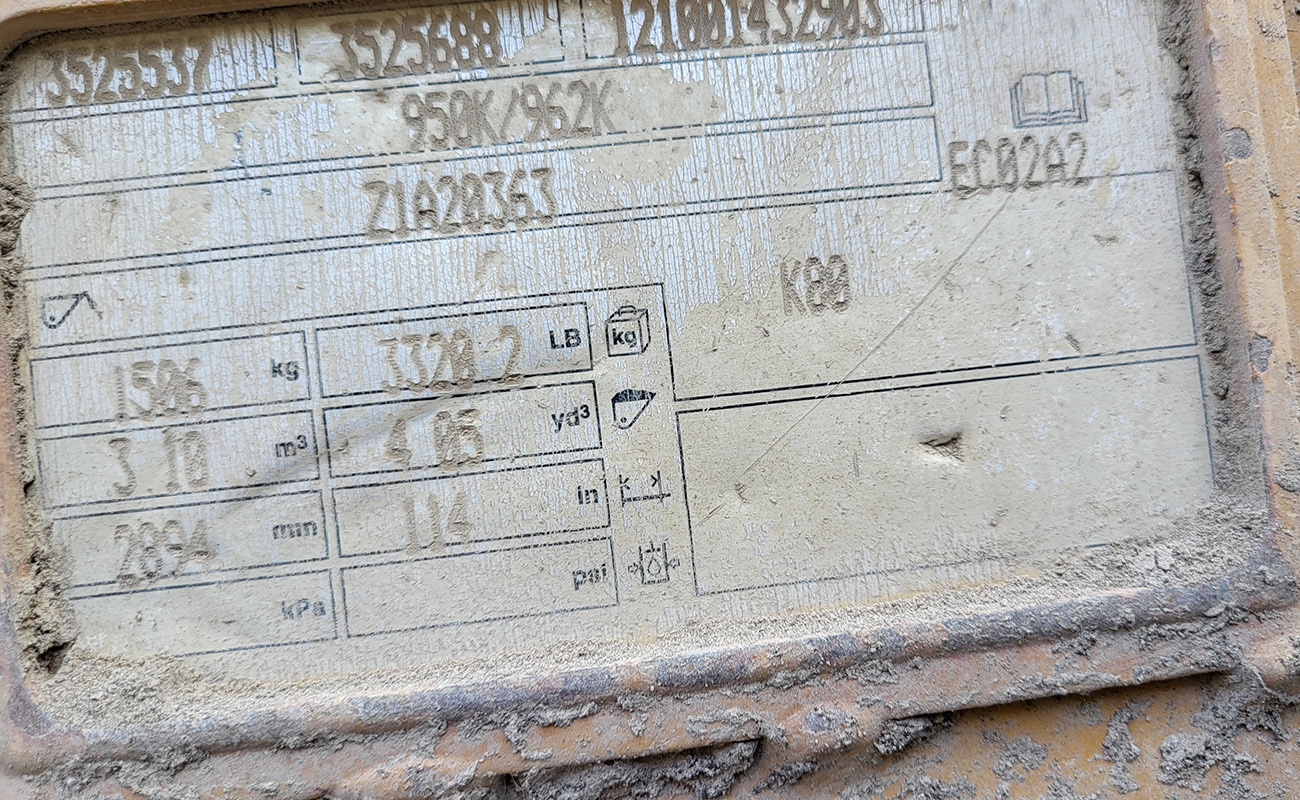

Further clues to finding the tooth system include identifying the make and model of the machine and knowing if the bucket is original or a replacement bucket from a different manufacturer. OEMs will often use exclusive systems on their own brand attachments.

Step 4

Finally, measurements and photos of your tooth system can also help solve the mystery.

Measure both the inside and outside dimensions of the tooth pocket — measuring from left-to-right and top-to-bottom. Also, providing the lip thickness of the bucket will point to the correct adapter size.

If you can provide pictures of the tooth pocket, retainer hole and the shank itself, our expert staff can quickly help identify the tooth system.

Once you know the type of tooth you need, you can use our helpful Tooth System Size Conversion chart to see which systems are comparable to what you are currently using.

Best of the Best

We work with top-of-the-line vendors to bring our customers the highest quality of teeth. Our vendors use heat-treated superior steel alloys for optimum strength and performance and have designed a variety of styles to best suit machine and application needs.

Heavy Duty Wear Upgrades

We also offer Tungsten Carbide Embedding for all digging teeth, which adds hardness to the parent material in the most vulnerable wear areas of the teeth, thus improving performance and prolonging the life of the parts.