WorkOur Projects

Featured Projects

SA RECYCLING SHIP LOADER PAN

SA Recycling commissioned SSAB engineering for a redesign of their ship loader pan to allow for an 80-degree tipping angle. The world-leading metal recycling and processing company was looking to load ships faster and more efficiently, without debris getting stuck in the pan.

With blueprints in place, Cutting Edge Supply handled the custom fabrication of the loader pan, which measured approximately 16 feet wide, nearly 22 feet long and 14 1⁄2 feet tall and weighed 30,400 pounds. Our shop used Hardox 500 Tuf to maintain the high strength, high hardness and toughness needed, while reducing the dry weight of the pan and allowing for an increased payload capacity.

Dredge Clamshell Bucket

Our California shop took on this giant Dredge Clamshell Bucket repair for one of our aggregate clients. It included replacing both moldboards with Strenx 700 material, replacing the rear triangle sections of both buckets with Hardox 450, installing new inside and outside liner packages with a mix of Hardox 450 and Duroxite clad plate, replacing support ribs on the back of both buckets with Hardox 450, fixing all cracks in buckets and head unit and converting both buckets to new ESCO U45 Ultralok hammerless adapters and teeth. Additionally, our team built up and line bored the bucket linkage, installed new bushings and pins, adjusted bucket stops for proper clearance of hydraulic cylinders, and more.

After several weeks of hardcore repair, our team painted it a bright red so as to be better seen when digging underwater.

CUSTOM XMOR BUCKET BUILD

Our team custom built this XMOR bucket for a CAT 390 from scratch.

Designed for high productivity and to improve cost efficiency, these patented XMOR excavator buckets are fabricated to exacting standards from SSAB Hardox and Strenx materials.

62-Yard Dipper Bucket Repair

Our ace welding team in Phoenix tackled this “big boy” repair job, including first fixing the structural and crack repairs, as well as machining and other customer specific custom mods. Our team also specializes in creating intelligent liner packages to better protect the rebuild. For this project, they installed a combination of Hardox steels to maximize wear life in specific areas of this mining dipper bucket.

CAT 994 BUCKET RESTORATION

This Caterpillar 994H loader bucket was originally custom built in-house by our team in 2015.

Thanks to skilled craftsmanship and the use of high quality Hardox steel, this bucket has outperformed and outlasted its OEM counterparts to deliver increased wear life, dependability, and value to the customer. After years in service with an Arizona mining property, it was time to come home in early 2023 for a complete refurbishment, again using Hardox materials.

Our Arizona team stripped this bucket down to a bare shell and gave it a second life. Along with using the toughest and hardest steels on the planet, this bucket’s performance is further augmented by using mechanically-attached Hensley “Turtle” wear protection in critical high wear areas to maximize wear life and minimize downtime due to field welding maintenance.

BOLT-IN TRUCK BED LINER

Cutting Edge Supply partnered with fellow Hardox Wear Parts member Austin Engineering to design a truly value-added truck bed liner package. Built by Austin Engineering, our Arizona shop handled final assembly on this CAT 789D truck bed, which included a 100% bolt-in Hardox 500 Tuf liner package. This unique package allows the end user to simply remove bolt-in liners in sections for preventative maintenance as they wear — without removing the bed or taking it out of service. This innovative solution yields greatly minimized downtime, labor and welding costs.

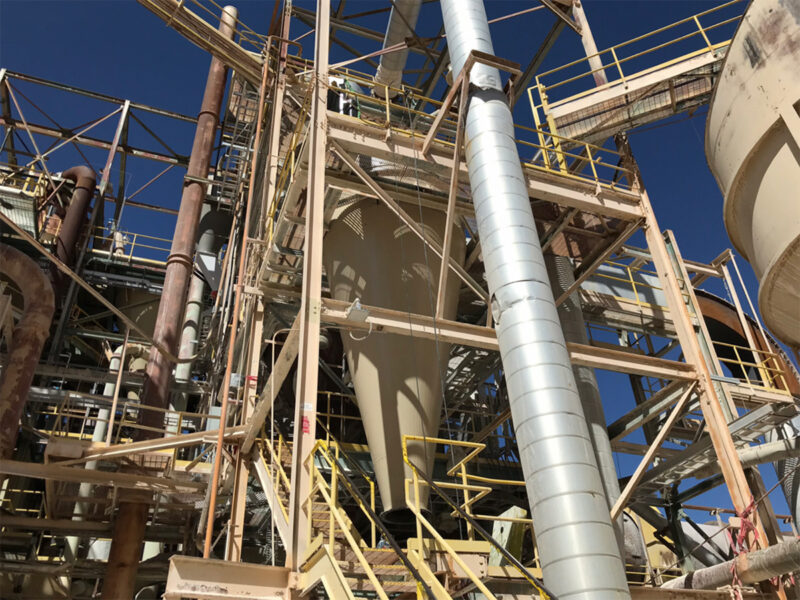

Cyclone Silo for Material Processing Plant

A break from the norm, Cutting Edge Supply took on this custom fabricated cyclone silo order for a material processing plant, featuring Strenx 700 for the base material, Hardox 450 lining and Duroxite wear parts.

Designed and built at our headquarters in Colton, California, the parts were then delivered by truck and assembled at the plant site.

Baler Cylinder Retube & Rebuild

Our skilled Chrome Craft repair shop in Sacramento retubed and rebuilt this 14”-diameter, 12-foot-long Baler cylinder for a waste disposal site. They used our Gemini Lathe machine to retube the cylinder, followed by chrome and grind on the rod and finally, a repack and reseal.

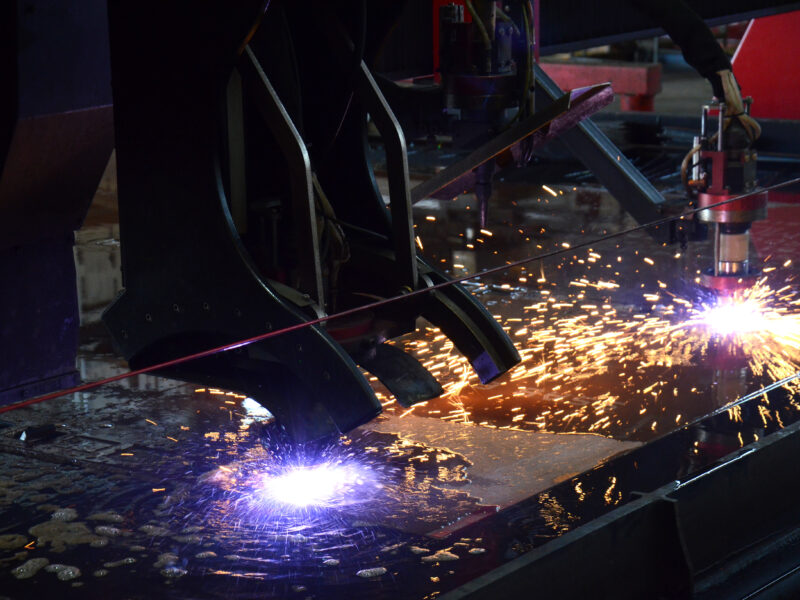

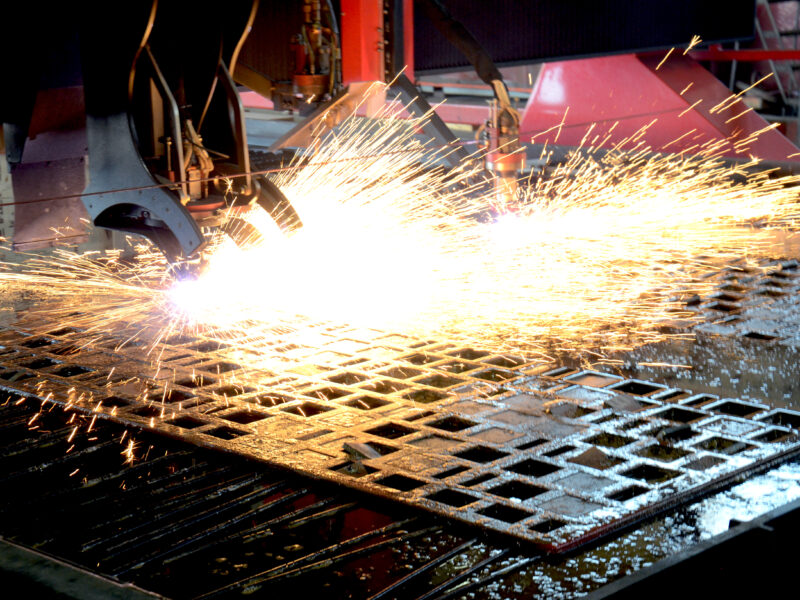

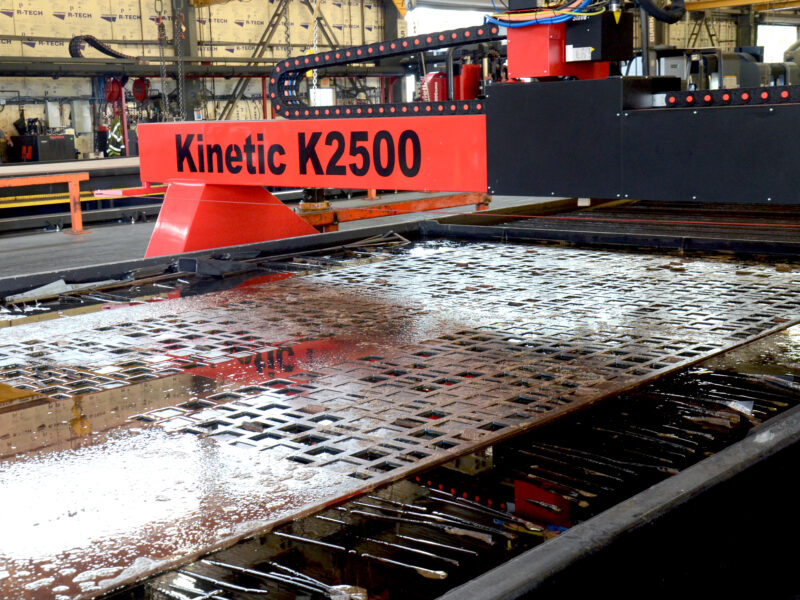

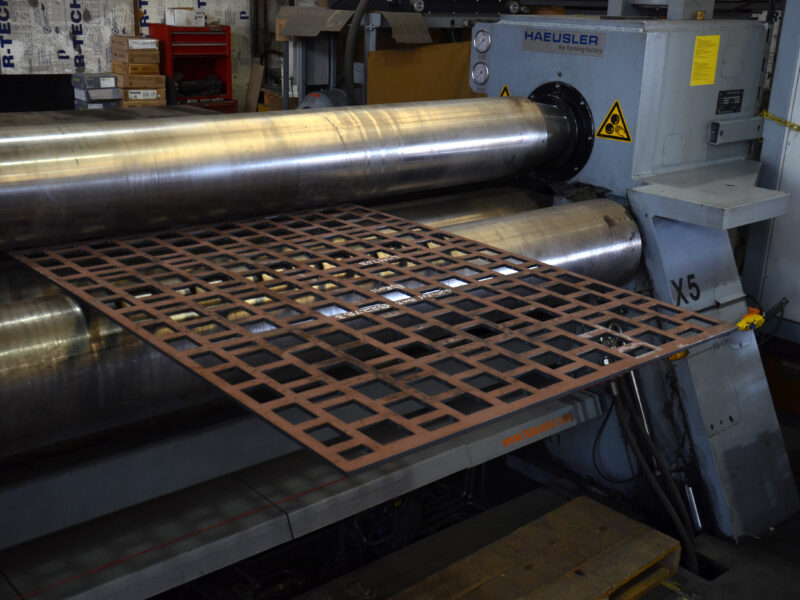

CUSTOM PUNCH SCREEN

Cutting Edge Supply offers custom made-to-order punch screens that outpace and outperform the competition. Normally, punch screens would use a 250 Burnell grade of steel. At Cutting Edge Supply, we’ve got a unique technique and process to make these punch screens out of Hardox 450, making them harder and more durable. Our draft & engineering team created the nesting for this screen, which was cut on our Kinetic 2500 Plasma table with dual-torch. The Hardox 450 3/8”-thick screen then went through our Haeusler Roll Press for forming. Hooks are formed through our Metso press breaks and then welded to the punch screen to form the retention system.