Savings & Quality

Our Chrome Craft division in Sacramento has been in business since 1963, setting the industry standard for quality when it comes to original or remanufacturing pins, as well as hydraulic components and other industrial machined parts including dozer connector parts and scraper and haul truck axle housings.

All work is done in-house from start to finish, allowing us to keep costs down, ensure quality and provide customers a speedy turnaround time.

Chrome Craft also stocks linkage pins, hitch pins, cylinder rods and dead axles, as well as reconditions pivot shafts, trunnions and axle housings.

Explore our product offering below.

pins

AFTERMARKET

-

Full line of CAT Pins for:

- Scraper Hitches (621-657)

- Loader Bucket and Linkage (950B to 994 and larger)

- Larger Excavator Bucket and Linkage (CAT 320 and up)

- Dozer and Ripper of all sizes

-

Mining Dipper & Cable Shovel (snubber pins)

-

Drag Line Bucket Pins & Bushings

ORIGINAL / REMANUFACTURED

What Makes Chrome Craft Pins Unique?

Chrome Craft manufactured pins incorporate only the highest quality materials and technology that meets or exceeds OEM specifications. Chrome Craft has also worked closely with OEM dealers and end users to develop a unique process for our custom and remanufactured pins that result in durable, wear-resistant pins that have no rival.

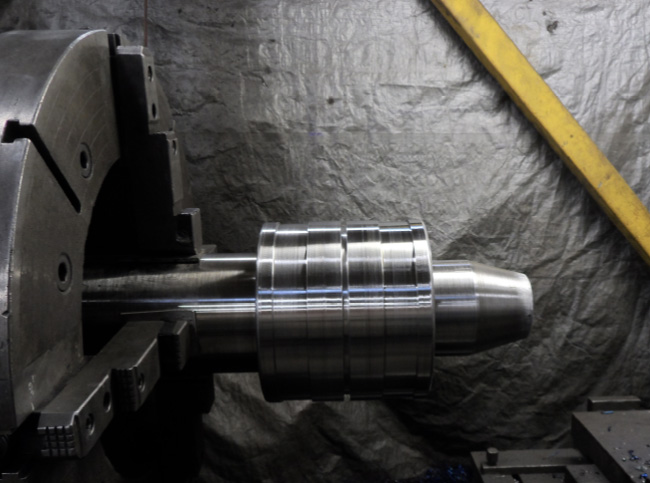

All Chrome Craft original and remanufactured pins are finished with an optimal layer of hard chrome. Our process avoids using excessive amounts of chrome, which would result in the chrome cracking. Our first step brings the pin to just under the finish size, with the original OEM hardness of the pin also met or exceeded. The pin is then put through precision machining, followed by hard chrome plating, which gives the pin more resistance to wear and scoring. Finally, the pin is polished to the final OEM diameter.

Why is Thick Chrome a Bad Thing?

If you have ever used thick-chromed pins, you probably found out the hard way that those pins did not hold up. This is because heavy deposits of chrome will eventually chunk off due to the hammering the pin is subjected to during use.

The life of a pin of even the best quality still depends on proper sizing of the mating bore or bearing. Putting a rebuilt pin in a loose bore will result in premature wear on the pin. The bores also need to be rebored or the bearings replaced to have a properly rebuilt machine, and this is something our team will also ensure is done correctly.

hydraulic parts

Cat Scraper Barrels and Rods (EXCHANGE)

JD and CAT Stabilizer Rods (EXCHANGE)

Custom-Made Hydraulic Rods

Custom-Made Cylinder Heads, Pistons & Eyes (also limited EXCHANGE)

Remanufacture or Full Repair of Hydraulic Cylinder Groups

For exchange availability and pricing information, call us at (800) 375-6986 with part number, make and machine model.

INDUSTRIAL MACHINED PARTS

Industrial Machined parts for Caterpillar equipment:

Trunnions for Scrapers & Dozers

Dead Axles & Pivot Shafts for Scrapers & Dozers

Remanufacture of:

Scraper & Haul Truck Axle Housings

Dozer Connector Blocks