Cutting Edge Supply Co-Founder Patented the Design for Plow-Bolt Hole

The year was 1963. Cutting Edge Supply was a single office in Downey, California. Then co-owner/operator, Ollie Cook, had a bright idea on how to decrease bolt breakage on blades.

He called it the “first improvement in plow bolt holes since the invention of the plow” and it was so beneficial that he was able to place a US patent on them.

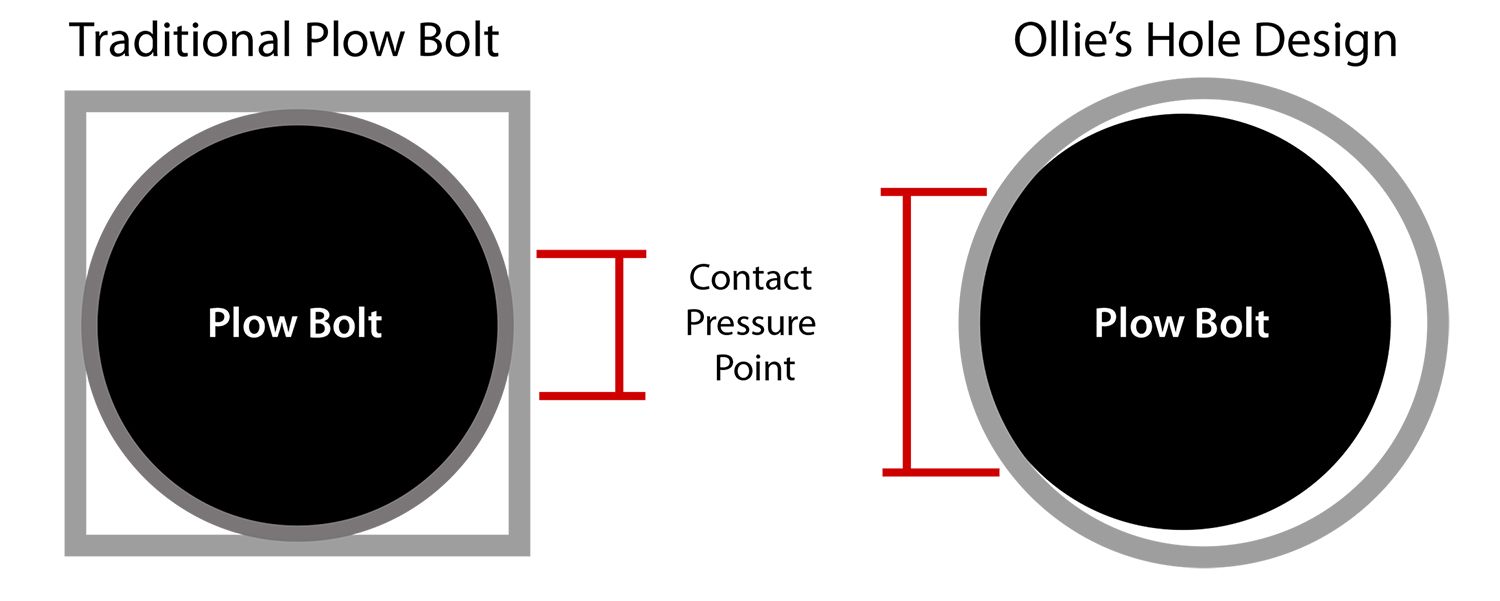

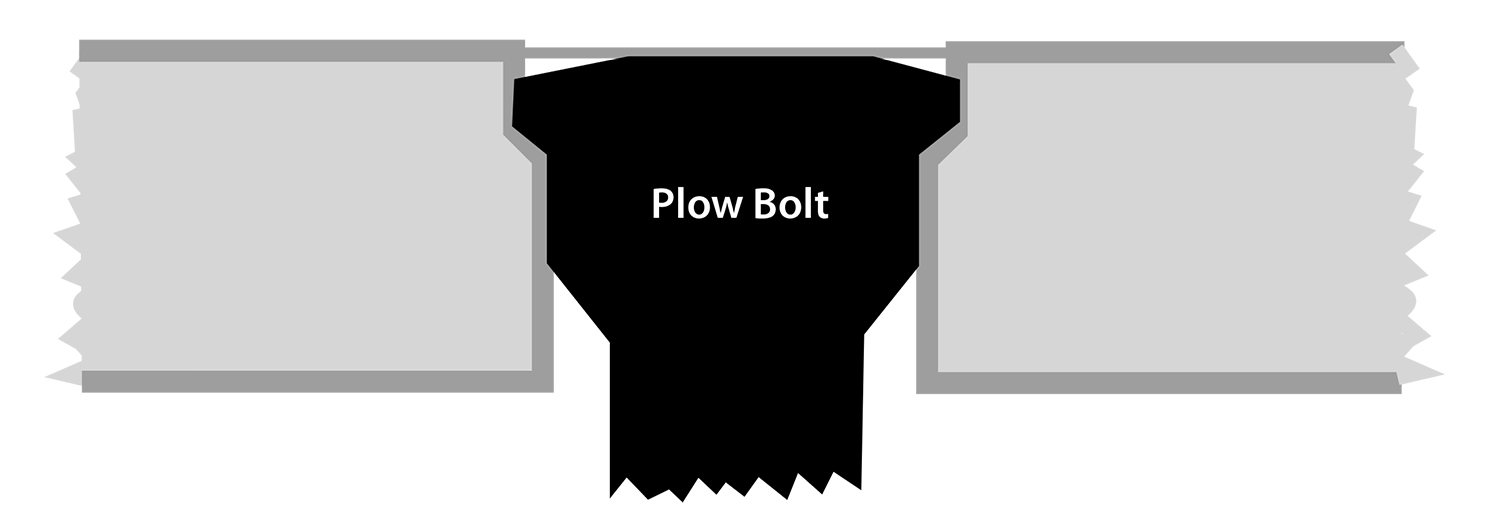

Ollie’s big idea was a new design of bolt holes for Cutting Edge Supply blades that was better suited to the shape of plow bolts. Standard bolt holes at the time were typically partially countersunk then punched square through the rest of the blade, leaving little contact between blade and bolt.

Traditional Plow Bolt installed in a blade – Profile View

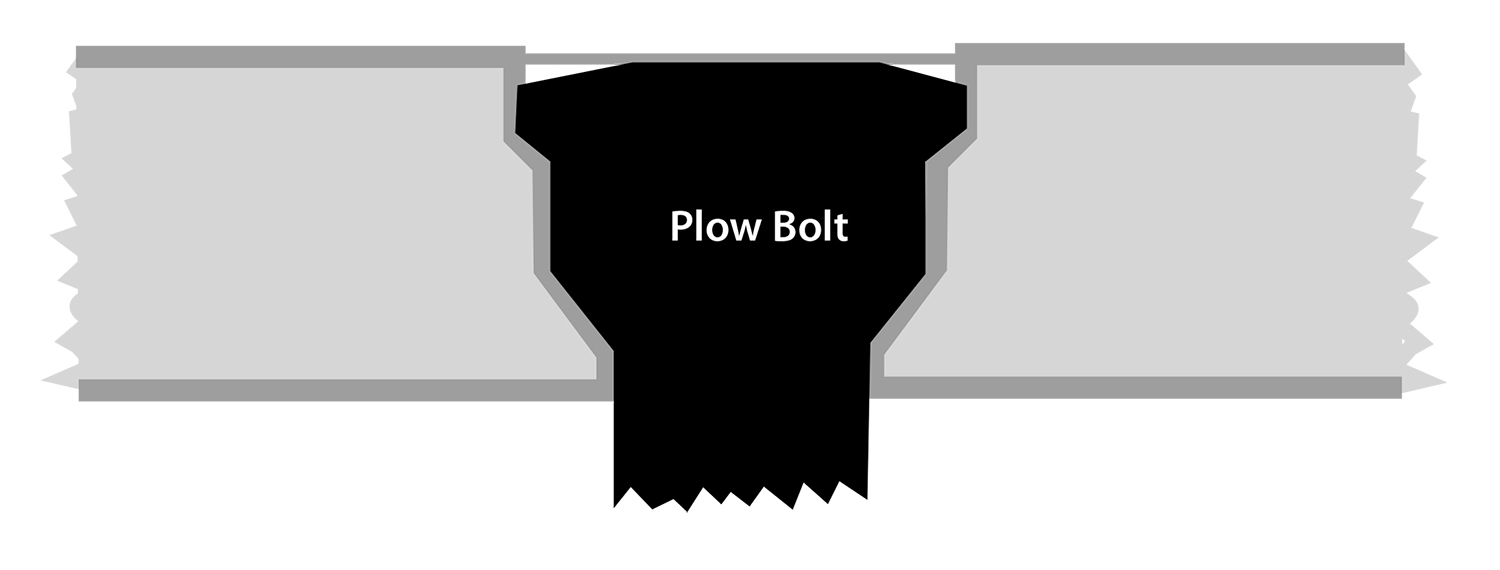

Ollie’s design was a tedious four step process. The blade was first drilled through 1 1/16” and then countersunk as normal. Next, the blade was square punched but not entirely through the blade. The hole was then hit with a reamer to remove any excess material blocking the round hole due to pressing. This left two round openings (one countersunk hole for the bolt head and one hole roughly the diameter of the bolt shank) on top and bottom with a square hole between them to lock the bolt in place. It eliminated the square hole around the bolt itself. Round holes increase surface area contact with the bolt at the pressure point. More contact means less force in a single area, thus reducing bolt breakage.

Ollie’s Patented Hole Design – Profile View

Ollie sold these new blades with no increase in price. Later other companies imitated the design including versions that were cast, though these often broke more easily. Because of machining ease and the steel strength from non-cast manufacturing, a square punch design or a CNC machined hole are favored in the market today. Due to improvements in steel alloys for both blades and bolts, the need for the design did not last forever but was revolutionary at the time. Like most improvements in any industry, standards and technology will change, but this is a proud note in the company history and a lasting example of our commitment to quality parts.

Top View Comparison