A Deep Dive into Our Chrome Craft Division

Baler Cylinder Rebuild (8″ diameter rod x 12″ diameter bore x 16 feet long)

In 2011, Cutting Edge Supply acquired Chrome Craft in Sacramento, California, further widening the company’s overall capabilities and expanding the product line. Whereas Cutting Edge Supply’s Colton and Phoenix repair shops primarily cater to mining, construction, aggregate and waste & recycling industries, the Chrome Craft shop addresses the needs of additional industries, including agriculture, food production and processing, plastic extrusion, automotive and oil fields and refineries.

Originally formed in 1963, Chrome Craft is a full-service machining, welding, hard chrome plating and precision grinding facility that sets the industry standard for quality when it comes to manufacturing pins and hydraulic cylinder components, as well as remanufacturing worn out pins or industrial machined parts back to the original OEM specs. The shop also offers complete hydraulic cylinder system rebuilds and repairs.

All work is done in-house from start to finish, which allows for keeping costs down, ensuring quality and providing customers a speedy turnaround time.

Shop foreman Dathan Louviere, who has been with the company for almost 27 years, says most customers are still surprised to learn of the shop’s wide-ranging capabilities.

“Despite the Chrome Craft name, most customers think we are only a machine shop and are very surprised to learn we are a chrome plating facility,” said Dathan. “I just had a customer in the other day who had no idea we do all of our chrome in-house, as well as ID grinding. Not a lot of our competitors, especially in Northern California, have the capabilities to do chrome plating, grinding and hydraulic repairs. You might have a machine shop or a hydraulic shop but not a shop that can also offer grinding, submerged arc welding for pin rebuilds or the chrome plating.”

That’s probably because hard chrome plating is hard.

“There are definitely challenges,” said Dathan. “It’s chemistry—so you are always mixing solutions and there are so many variables.”

Our Hard Chrome Tanks can handle lengths up to 288″ and widths up to 72″.

Fortunately, the Chrome Craft crew’s extensive experience allows them to successfully navigate the complications.

“Because of the knowledge we have accumulated over the years, we’ve been able to narrow that chemistry down – based on this amount of current, you get this much deposit as long as your chrome solution % is this,” shared Dathan. “Still, there are contaminates that get into those tanks, and we monitor that closely. If we have any pitting, we start trouble shooting — making sure our chemicals are up to the standard that they need to be at and running a ceramic porous pot in the tank to pull out any impurities. We are always checking our solutions by sending them out to have analyzed by labs.”

The team is also extremely particular about delivering only the optimal layer of hard chrome and avoiding excess.

“The nature of chrome is that it is super hard so we stay away from plating heavy,” explained Dathan. “If something hits the chrome hard enough to impact and cause a fracture in the chrome, as it starts heating up in the application it’s being used in, it will cause the chrome to delaminate. Then you start getting big chunks of this super abrasive, hard material coming off. You can imagine if that is inside a cylinder or bearing race — it just tears stuff up. Anything over .015 a side, the likelihood and risk of that happening is a lot higher, so we keep it under that to make sure we avoid cracking.”

The shop applies this hard chrome plating philosophy to all original, custom pins formed in house, as well as the remanufactured pins, resulting in durable, wear-resistant pins.

“We rebuild all pin cores with our submerged arc welding — I call it rotisserie-style welding, and then they go through precision machining and hard chrome plating,” said Dathan. “I have heard from many customers who use our rebuilt pins that they get more longevity out of our pins versus what they get from the OEM.”

On the hydraulic cylinder and component repair side, once again, the hydraulic specialists are the best in the business.

“When I first got here, there were guys who had been here for 30 years and they passed that knowledge down,” said Dathan. “I’ve done the same and we’ve got guys in hydraulics who have been with us for at least 15 years. They had also been at other shops prior to coming here so there’s extensive knowledge and know-how to handle hydraulic repair from any industry — whether it’s a simple reseal job or a complete overhaul.”

That experience was recently put to the test with a Baler Cylinder for a scrap metal facility. The team was able to rebuild the rod and cylinder, as well as reseal the unit for half the price of what it would cost to purchase a full unit from the manufacturer.

But there was a slight hitch.

“In order for us to take the job, we had to figure out how to reengineer the flanges on the ends of the barrel,” said Dathan. “They had the threads of the holes drilled and tapped halfway into the barrel and halfway into the flanges and there was a seam. Even with all my years at the shop—as well as the other guys in the shop—it was something we had never seen. Based on some things I had done in the past, we figured out how to recreate the flange and maintain that seam.

“I think that’s what I love the most about my job,” he continued. “I really enjoy the challenge and the variety of the things that we do because it is not always the same. I’m out in the shop every day machining just like a lot of the other guys, but we have so many unique projects, and it allows me to use my mind and creativity to come up with solutions. Any time my guys run into an issue, they find me to take a look so that we can fix the problem at hand.”

In addition to the versatile shop services, ChromeChrome Craft also stocks linkage pins, hitch pins, cylinder rods and dead axles, as well as reconditions pivot shafts, trunnions and axle housings.

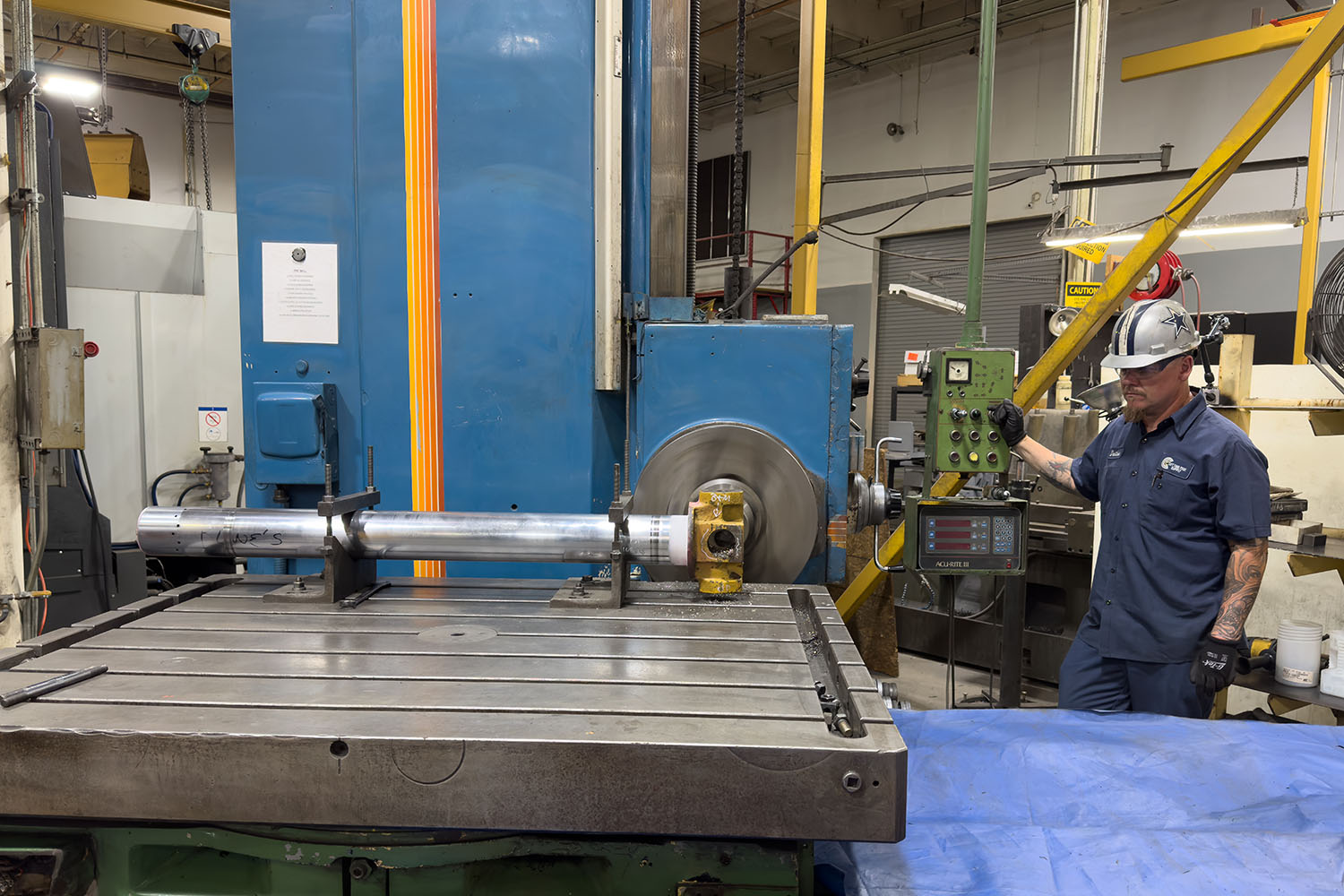

Shop Foreman Dathan Louviere machining a CAT 657 Ejector rod.

This grinder dates back to WWII, and originally had a tracer to make cannon barrels. Here, our tech is grinding the internal bearing.

Submerged arc welding to thicken the diameter of a worn-out pin for a CAT loader.

Polishing!